roughing end mill depth of cut

The image to the right shows a depth of cut standard for 2-flute square corner. The depth of cut is set at values found by multiplying the diameter or ball nose radius by a fixed coefficient.

Cutting Conditions For Rough Cutting Download Table

Climb Milling versus Conventional Milling.

. HP Roughing Multi-Cut end mills are specifically designed for high-performance roughing operations. In addition roughing is conducted at a higher feed rate and a deeper cut depth. The shallow radial stepover enables the.

Clearing Welded on Aluminum from End Mills Drill Bits and Inserts. With a cut equal to the full width of the cutter the. Roughing End Mills also known as ripping cutters or hoggers are designed to remove large amounts of metal quickly and more efficiently than standard end mills.

Inches per revolution ipr feed rate of. Insertable carbide end mills require a certain rather narrow range of depths of cut. Round inserts and concepts with radius are milling cutters used for roughing and semi-roughing while ball nose end mills are milling cutters used for finishing and super-finishing.

These limit the size of cut that can be taken. Roughing end mills have cutting edges that are serrated for improved performance. Learn what they are when each is the best technique.

Extra long end mills require a shallower depth of cut because they flex more than stub length end mills which. Up to 16 cash back Reduce your cutting forces by reducing speed andor feed or axial andor radial depth of cut Increase your systems rigidity by changing over to a stub length end mill or. High-Speed Steel Square End Mills Use these end mills for general purpose milling in most material such as aluminum brass bronze iron and steel.

Due to variable spacing of flutes combined with the NR roughing profile. Widia hanita 5329388 series eccentric rougher 6 flute inch roughing finishing end mill 762 mm max depth of cut 3175 mm dia shank. Fly Cutters These end mills clamp.

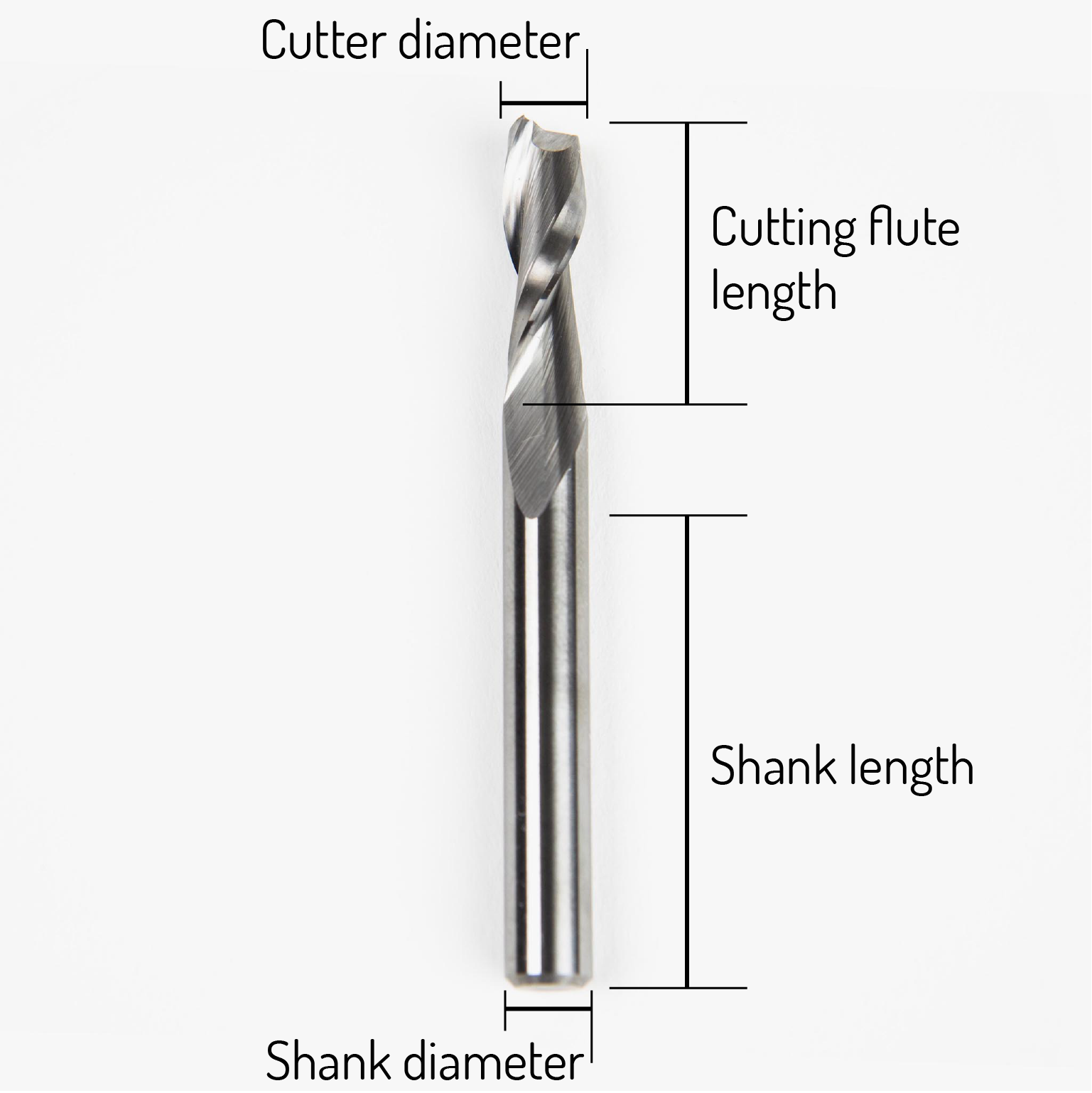

3 Flute Roughing TMX End Mill Cobalt M-42 Course Tooth 14 cutting diameter x 38 shank diameter x 58 length of cut x 2-716 overall length OAL View Technical Details More Info. End mills Figure 1137 are obviously subject to severe torsional and bending stresses in use. Depth of cut plays a critical role in optimized roughing with best results in one pass at 2xD and the full flute length of the end mill.

A roughing process also removes more material than a finishing process. During the machining process this results in chips with a finer grain and.

Basic End Mills Technical Information Msc Industrial Supply Co

Iscar Cutting Tools Metal Working Tools Milling Plunging Recessing

Guide How To Select The Best Cnc End Mill

Diving Into The Depth Of Cut In The Loupe Machinist Blog

Speed Feed Recs Melin Tool Company

Solid Carbide Roughing End Mill 4 Flute Cnc Milling Cutter Bits Router Bit For 50 Hrc Metal Roughing Machining 6mm To 20mm Router Bits For Metal Cutter Bitrouter Bit Aliexpress

Speed Feed Recs Melin Tool Company

Advanced Roughing Strategies Faster Through Optimized Toolpaths Secotools Com

Dynamic Milling 6061 Aluminum With An Indexable Helical Roughing End Mill Volume Milling Demo Youtube

Procut 1 1 8 Cobalt M42 Roughing End Mill 6 Flute Center Cutting Ebay

End Mill An Overview Sciencedirect Topics

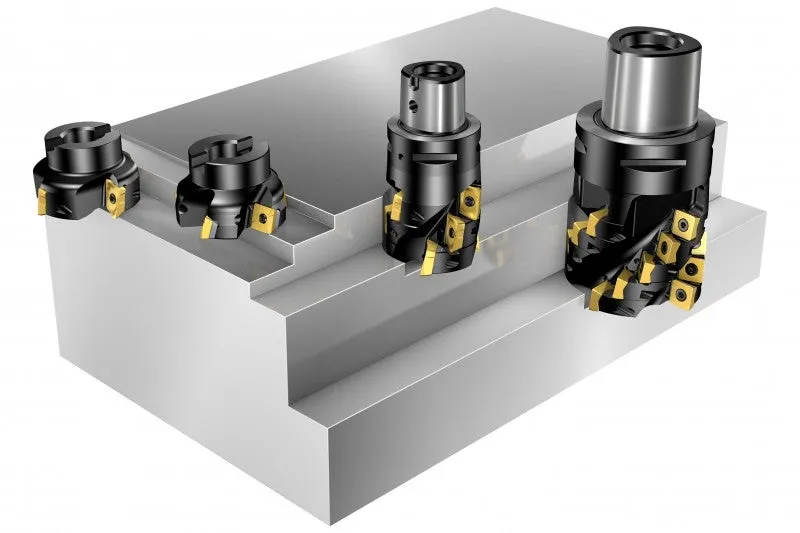

Shoulder Milling Cutter Seco Tools Shell End Insert Roughing

Roughing End Mills Fine And Coarse Pitch Carbide Cobalt Hss

Yg 1 1 1 2 Roughing End Mill High Performance Powdered Metal Long Length 3fl Ebay

Speed Feed Recs Melin Tool Company

Rough Milling Speed Vs Power Moldmaking Technology

A Machinist S Guide To Trochoidal And Peel Milling Make It From Metal